How to read markings on rims? Rim parameters, ET, and their properties.

Aluminum wheels are not only an aesthetic addition to a car but also a key element influencing its driving characteristics. Thanks to modern production technologies, alloy wheels offer exceptional lightness, durability, and improved braking system cooling. They are the ideal solution for drivers who value both dynamic driving and elegant vehicle appearance. What are their key advantages? How do they impact driving comfort? How can you read their parameters?

Advantages of aluminum rims, why is it worth investing in them?

✅ Lightweight construction – a key advantage of aluminum rims

One of the greatest advantages of aluminum rims is their low weight compared to steel rims. The use of lightweight aluminum alloys allows for a significant reduction in wheel weight, which directly impacts vehicle handling, performance, and fuel consumption.

Why are aluminum rims lighter?

Aluminum rims are made from light metal alloys, primarily aluminum with additions of magnesium, silicon, or titanium. Unlike steel rims, which are made from a much heavier raw material and require thicker structural walls, aluminum rims can be thinner while maintaining high strength. Modern production methods, such as low-pressure casting, flow-forming , and forging, result in even lighter and more durable rims.

How does the reduced weight of rims affect driving?

- Improved acceleration and vehicle dynamics. The mass of the wheels is known as unsprung mass, meaning that mass not supported by the suspension. The lower this mass, the easier the vehicle gains speed, and the less energy the engine uses to propel the wheels. This is especially important in sports cars and electric cars, where any reduction in mass improves efficiency.

- Shorter braking distances. Lighter rims mean less inertia, which translates into more efficient braking. Brake discs and pads wear slower, and braking becomes more precise and effective.

- Less load on the suspension. Reducing unsprung mass means less force acting on suspension components such as control arms, shock absorbers, and springs. This allows the vehicle to better absorb bumps, resulting in improved ride comfort and longer suspension component life.

- Fuel savings. A vehicle's lower weight means less energy is required to propel it. This means fuel consumption can be reduced by up to several percent, especially on longer routes and with dynamic driving. In the case of electric cars, reduced weight translates into a longer range on a single charge.

- Improved handling and steering precision. Aluminum wheels, thanks to their lightness, improve vehicle balance and make the steering more precise. The car becomes more predictable in corners and easier to maneuver, especially at higher speeds.

✅ Lower fuel consumption – reducing unsprung mass means lower fuel consumption and greater range in electric cars

✅ Better brake cooling – aluminum construction and open rim design ensure more effective heat dissipation

✅ Exceptional corrosion resistance – protective coatings protect against moisture, salt and mechanical damage

✅ Better aerodynamics – optimized shape reduces air resistance and improves vehicle stability

✅ Modern design – a wide range of patterns, colors and finishes allows you to match the rims to any style

Thanks to the use of advanced technologies—such as low-pressure casting, flow-forming, and forging—our wheels combine lightness with maximum durability. They're the perfect choice for drivers who value both sporty character and everyday driving comfort.

Basic rim parameters that should be checked before purchasing

The basic markings on rims include: rim size, number of bolt holes, mounting bolt spacing, rim width, ET, and center bore diameter. All of these markings refer to the geometry, or dimensions, of a given rim. Let's see which specific dimensions correspond to a given parameter. Deciphering the symbols on rims will help us with this.

Rim dimensions and markings

The graphic below shows the basic geometric parameters of rims. We also provide details about each designation.

[A] Rim size – this is the diameter of the entire rim, given in inches. The manufacturer pre-determines the possible rim sizes for a given vehicle. This is important because it allows the entire wheel to fit within the wheel arch. It also affects the size of the braking system. A large brake disc with a multi-piston caliper requires a rim that can accommodate the entire system. Therefore, it's best to use rims in the size specified by the manufacturer. Any change to a size other than the manufacturer's recommended size must be preceded by appropriate verification. Vehicles with existing warranties may also void their warranty.

[B] Rim width – measured between the inner surfaces of the rim flanges. It is given in inches. When selecting tires for a rim, consider this parameter and the car manufacturer's recommendations. Rim width is a parameter that influences whether the rim will fit in the wheel arch and avoid rubbing against it – for example, when turning.

[C] Bolt spacing and number – this parameter for each rim is always given in the axb [mm] format, where a is the number of mounting holes and b is the hole spacing, i.e., the diameter of the circle containing the holes. They are always evenly spaced and axially aligned. The diameter of this circle, unlike the diameter of the entire rim, is expressed in mm. The number of mounting holes must correspond to the number of bolts (studs) on the vehicle's hub.

[D] ET - The ET parameter (from the German Einpress Tiefe) is also known as offset. It is given in millimeters and is closely related to the width of a specific rim. It describes the distance between the mounting surface and the rim's axis of symmetry.

[E] Rim center bore - this is a measurement in millimeters and specifies the diameter of the rim's center bore. If the car has a smaller hub diameter, additional centering rings can be used.

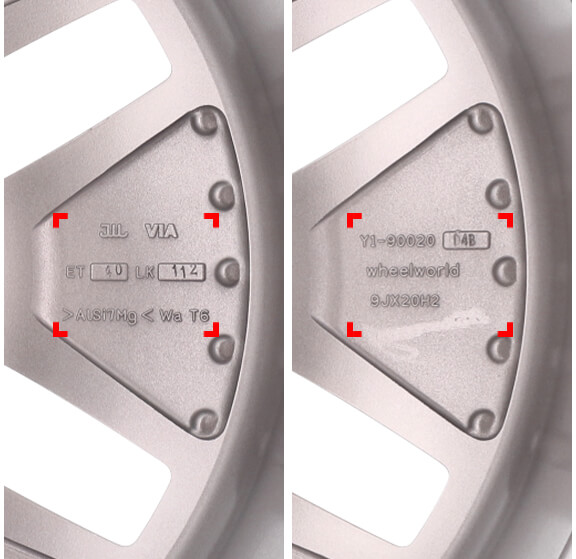

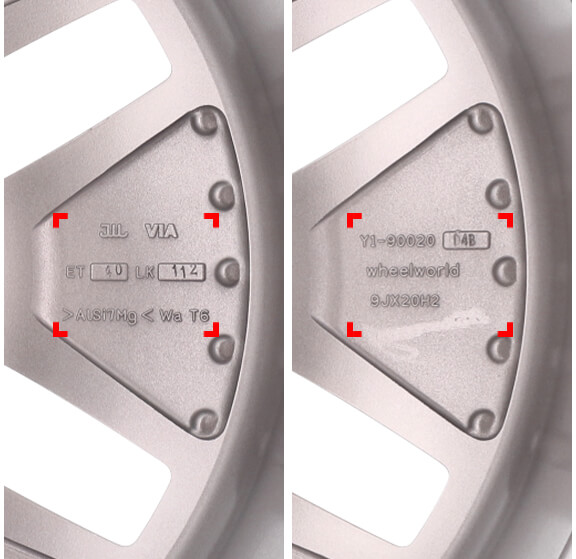

Where to look for markings on aluminum rims?

Each rim model has its own marking, assigned by the manufacturer. You can find it on the rim itself— often embossed on the inside of the rim , for example, on one of the spokes. The photos below show one of our aluminum rims. As you can see, all markings are easily readable.

Rim markings can also be found on the box or product data sheet in our online rim and tire store. You can also find the aluminum rim's technical parameters there, helping you choose the perfect fit for your car.

Where to look for markings on steel rims?

Markings are assigned by the manufacturer. As with aluminum rims, steel rims also have embossed markings – each manufacturer places them differently, but you can usually find them on the front of the rim . These markings will help you perfectly match the steel rim to your car. The photos below show the steel rims available in our store, and as you can see, you can easily read all the technical parameters.

What do the symbols on the rims mean?

An example rim marking might look like this: 17x7.5J 5x112 ET38 66.5 . What do we learn from this notation? Let's see:

- 17 - rim diameter expressed in inches,

- 7.5 - rim width expressed in inches,

- J - is a flange profile dedicated to passenger cars,

- ET38 - is the offset of the car rim of 38 mm,

- 66.5 - diameter of the central hole expressed in mm.

How to read the ET of a rim?

ET is a dimension given in millimeters. It represents the distance between the mounting plane (the contact surface of the rim with the vehicle hub) and the rim's axis of symmetry (the plane passing through the center of the rim's width). The figure below shows which distance is the ET parameter.

To determine the ET, simply measure the distance between any point on the mounting surface inside the rim, directly adjacent to the wheel hub, and the rim's axis of symmetry. However, in practice, this isn't always easy. Furthermore, the measurement must be precise to the millimeter. Therefore, the ET marking on rims is commonly used. This facilitates quick reading of this parameter's value.

ET calculations are especially important if you want to use rims with a different width than the factory ones. Wider wheels than the original are one of the most common tuning procedures. The position of the rim relative to the vehicle depends not only on the ET value. The width is also important. The edge of a 9.5" rim will protrude further from the center of the vehicle than a 7.5" rim – even if their ET values are identical.

The correct selection of rims for each car

Wheel markings contain a wealth of important information, so before purchasing the perfect wheels for your car, carefully verify these parameters . Our configurator is helpful – both by car model and wheel size. If you have any doubts, our qualified team will be happy to help you choose the right alloy wheels.

Aluminum rim tests – what durability do they offer?

Before an aluminum wheel is released to the market, it must pass a series of rigorous durability tests, compliant with international standards such as JWL, VIA, SAE, and TÜV. Premium models are often subjected to even more demanding internal manufacturer testing, ensuring their high quality and safety. Compared to steel wheels, aluminum wheels are characterized by greater stiffness and resistance to deformation, translating into better driving characteristics. Below are key durability tests that determine the durability and reliability of aluminum wheels.

✅ Static load test - checks the maximum load a rim can withstand under vertical pressure. Standard rims must withstand a minimum load of 600-800 kg per wheel (depending on the vehicle type approval and class).

✅ Fatigue test - tests the rim's resistance to sustained loads. Under simulated conditions, the rim undergoes 100,000-1,000,000 stress cycles, representing its long-term use. This includes radial and torsional tests, simulating driving on uneven terrain and dynamic cornering.

✅ Impact test - simulates hitting a curb or pothole. A 225-350 kg weight is dropped onto the rim from a height of 230 mm, generating impact energy of 5,000-7,500 J. The rim must not crack in critical areas or cause a sudden loss of tire pressure.

Test standards are designed to ensure the wheel can withstand extreme conditions that rarely occur in real life. For example, a fatigue test simulates driving for hundreds of thousands of kilometers in a short period of time, allowing for accelerated durability testing. Premium aluminum and forged wheels perform best, characterized by high stiffness and resistance to extreme conditions. Models certified by JWL, VIA, SAE, or TÜV guarantee the highest quality and safety. Aluminum wheels are not only stylish but above all durable and reliable on the road!

Modern design

Modern design Perfect fit

Perfect fit High durability

High durability Free shipping within 24 hours

Free shipping within 24 hours

Individual project

Individual project Dedicated caregiver

Dedicated caregiver