Alloy Wheels Without Secrets

A rim is the part of a car's chassis that houses a tire, or a tire and inner tube in the case of older technology. Rims are most often made from a mixture of aluminum or steel alloys. In the case of rims used in car racing, the rims are made from a more durable, lighter magnesium alloy. Research is currently underway on plastic rims. You can find more about plastic rims in the article "Are Aluminum Rims a Thing of the Past? " We are primarily interested in aluminum rims, and we will focus on them in this article.

Advantages of aluminum rims

The lower weight of the product compared to steel rims - this feature guarantees slower wear and tear of the car's components, which is not without significance in times when cars are equipped with increasingly sophisticated, more complex and therefore more expensive suspension components.

Greater care and precision of manufacturing – aluminum rims are made with a precision of up to 0.5 mm, while for steel rims it is currently only 1-1.2 mm, which results in smaller deviations.

Greater durability – Aluminum rims are much more resistant to dynamic impacts than steel rims. It's a myth that steel rims are more durable. Upon impact, steel rims will dent and immediately lose their surface finish, which can have dangerous consequences. Aluminum rims absorb impact energy due to their plastic nature.

More efficient cooling of the braking system – the design of aluminum rims ensures better airflow and, consequently, more effective cooling of the braking systems. This not only improves their efficiency but also their service life.

A more striking and interesting form , depending on the vehicle owner's preferences, the chosen rim design can emphasize the car's sporty yet elegant character. Contrary to appearances, choosing the right rims can dramatically change the car's appearance.

Technical parameters of aluminum rims

The next issue we'd like to discuss is the basic technical parameters of aluminum rims. Each of these parameters plays a significant role in selecting rims for your car.

1) Diameter - presented in inches (1 inch = 2.54 cm). The manufacturer determines the wheel size that can be fitted to a vehicle. For example, an Audi A4 B8 with a 2.0 TDI engine can accept rims from 16 to 20 inches. Generally, the larger the vehicle's displacement and power, the larger the minimum rim size. This is due to the need for more effective brakes, which in turn changes the diameter of the discs and calipers.

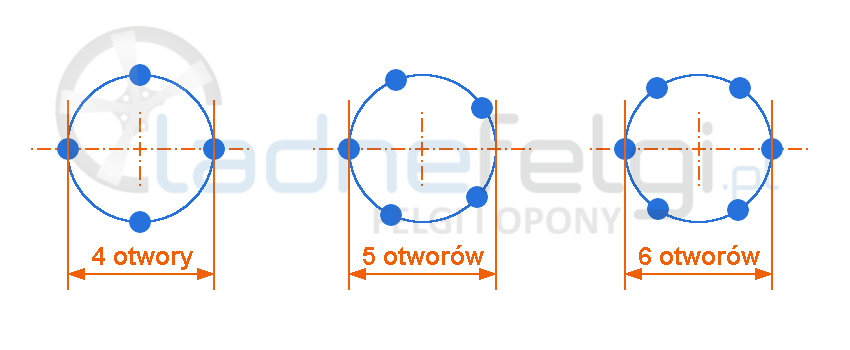

2) Spacing – A very important parameter is the number and spacing of mounting bolt/nut holes. Spacing is simply the diameter of the circle containing the centers of these mounting holes. The diameter of the circle is given in millimeters.

The wheelbase is a parameter that must be strictly adhered to. It's possible to change the wheelbase using wheel spacers. This spacer is bolted to the vehicle's hub, and then the rim is mounted with a second set of nuts.

The illustration below shows the correct way to check the stud spacing:

3) ET - Literally, it stands for immersion depth, also known as offset (in English), and colloquially, inset. Offset is most often given using the symbol ET. It defines the distance between the rim's mounting plane (the plane where the hub and rim meet) and its vertical center of symmetry. For both steel and aluminum rims, positive and negative values can be encountered. With a zero ET value, the mounting plane is located exactly on the vertical axis of symmetry. In summary: the smaller the offset, the further out the rim protrudes. Service manuals only list the parameters of currently installed rims. However, the manufacturer specifies the range that can be used. It is a mistake to rely on the parameters of steel rims when selecting aluminum rims.

4) Width - Rim width is measured between the rim flanges. Rim width is given in inches. Tires should be selected based on the rim, tire, and vehicle manufacturer's recommendations. Nowadays, we have a very wide range of tires, so choosing the right ones shouldn't be a problem. If an authorized service center tells us we can't use tires or alloy wheels other than those recommended by the manufacturer or acceptable substitutes from the service manual, it's usually a lack of knowledge or a marketing ploy.

5) Centering bore – this is simply the diameter of the hole in the rim, which has been adapted to the specific dimensions of the car. However, it often happens that the centering bore is larger than the diameter of the car's hub. In such cases, a centering ring must be used. Centering rings are made of plastic because once the rim is bolted to the car's hub, no force is applied to them. They are used to center the wheel and eliminate vibration.

6) Load capacity refers to the permissible load per wheel. For vans and campers, reinforced rims are recommended, with a load capacity of over 1000 kg per wheel. We also offer such rims.

Aluminum rims at LadneFelgi.pl

We encourage you to use the aluminum wheel configurator on our homepage. By selecting your vehicle's make, model, and capacity, you'll receive wheels that fit your vehicle. Our RacingLine wheels are covered by a 3-year warranty and have the required certifications . If you have any difficulties selecting wheels, please contact our helpline.

In the next article we will describe the methods of producing aluminum rims.

author: LadneFelgi.pl

Modern design

Modern design Perfect fit

Perfect fit High durability

High durability Free shipping within 24 hours

Free shipping within 24 hours

Individual project

Individual project Dedicated caregiver

Dedicated caregiver