Dual mass flywheel – what is it, how does it work, and what symptoms indicate its failure?

The dual-mass flywheel – commonly known as the "dual mass flywheel" – is a key, though often problematic, component of modern drivetrains. Its function is to dampen torsional vibrations from the engine, significantly improving driving comfort and protecting the gearbox and clutch. Many drivers ask: what is a dual-mass flywheel, what is a dual-mass flywheel, and when should you service a dual-mass clutch? In this guide, we'll explain how dual-mass flywheels are constructed, how they work, which cars they're found in, what symptoms indicate a dual-mass flywheel failure, the risks of driving with a damaged flywheel, how much a replacement costs, and whether it's worth considering a rebuild.

How Does a Dual Mass Flywheel Work? – The Key to a Smooth and Comfortable Ride

Role in damping torsional vibrations of the engine

A dual-mass flywheel (or dual- mass flywheel ) is a component of the drivetrain designed to dampen torsional vibrations generated by the engine. Internal combustion engines don't transmit torque perfectly evenly—each ignition is a pulse. Diesel engines and designs with fewer cylinders (e.g., in-line 3 and in-line 4) in particular produce more pronounced torque fluctuations, which, without damping, would cause jerking, noise, and accelerated component wear. The dual-mass flywheel acts as a filter: thanks to arc springs and friction dampers, it smooths out torque pulsations , resulting in a more stable idle, greater driving comfort , and protection for the gearbox and driveshafts. In practice, dual-mass flywheels reduce the transfer of vibrations to the dual-mass clutch and, consequently, to the transmission, making the entire system quieter and smoother.

Cooperation with the clutch system

The dual-mass flywheel is an integral component of the clutch assembly – it operates between the crankshaft and the disc pressed by the pressure plate . It absorbs most of the vibrations and momentary torque peaks, allowing the clutch to be simpler and lighter , and its facings to be less subjected to shock loads.

The effect for the driver is:

- smoother starting and gear changes

- less jerking at low revs

- quieter operation of the drive and slower wear of the gearbox components

In short: the dual mass stabilizes the engine's jerking motion, and the dual mass clutch efficiently transfers the already smoothed torque to the gearbox.

How is a dual-mass flywheel constructed? – Engineering for comfort

Two masses and a damping system

The dual-mass flywheel consists of two cooperating discs:

- Primary mass – rigidly connected to the engine crankshaft ,

- Secondary mass – on the side of the gearbox to which the clutch is bolted

Both masses can rotate relative to each other by a small angle, and a damping system operates between them:

- arch springs of different stiffness (often in several degrees, arranged in channels, usually filled with grease of a specific viscosity),

- friction dampers and sliding spacers that dissipate vibration energy ,

- angle limiters that protect the system against excessive deflection during sudden changes in torque.

A centrally located bearing or guide sleeve ensures alignment and smooth movement between the masses, minimizing friction and wear. This dual-mass design effectively absorbs torque pulsations and isolates vibrations from the gearbox.

Materials and precision of workmanship

Key components of a dual-mass flywheel are typically made of high-strength steel , heat-treated (hardened, tempered) and precision-machined . Arc springs are selected for their spring-damping characteristics , and friction surfaces are selected for their consistent friction coefficient and temperature resistance. The entire assembly is dynamically balanced , as even slight deviations would cause vibrations at high RPMs. This component operates under high variable loads, requiring precise manufacturing and adherence to lubricant parameters and assembly tolerances – these factors determine the durability and efficiency of the entire system.

What cars have dual mass flywheels? – From diesel to petrol

Dominance in diesel engines

Dual mass flywheels have become practically standard in diesel engines. The dual mass flywheel effectively manages the pronounced torsional vibrations and torque pulsations typical of diesel engines (high compression, strong combustion pulses at low revs). This reduces noise and jerking, while the gearbox and driveshafts are better protected against impacts. The use of dual mass flywheels has also helped manufacturers maintain low idle and cruising speeds, facilitating compliance with emission standards and reducing fuel consumption—without sacrificing comfort.

More and more often in petrol engines

Dual mass flywheels are becoming increasingly common in gasoline engines, especially in small , turbocharged (downsized) engines and more powerful sports engines. Today's gasoline engines, with fuel economy in mind, operate at lower revs and generate noticeable torque pulsations that require damping . A dual mass flywheel helps maintain refinement, smoothness at low rpm, and protects the drivetrain. This is a clear trend: with the widespread use of small turbo engines and tightening comfort and emission requirements, dual mass flywheels are finding their way into an increasingly wider range of gasoline cars.

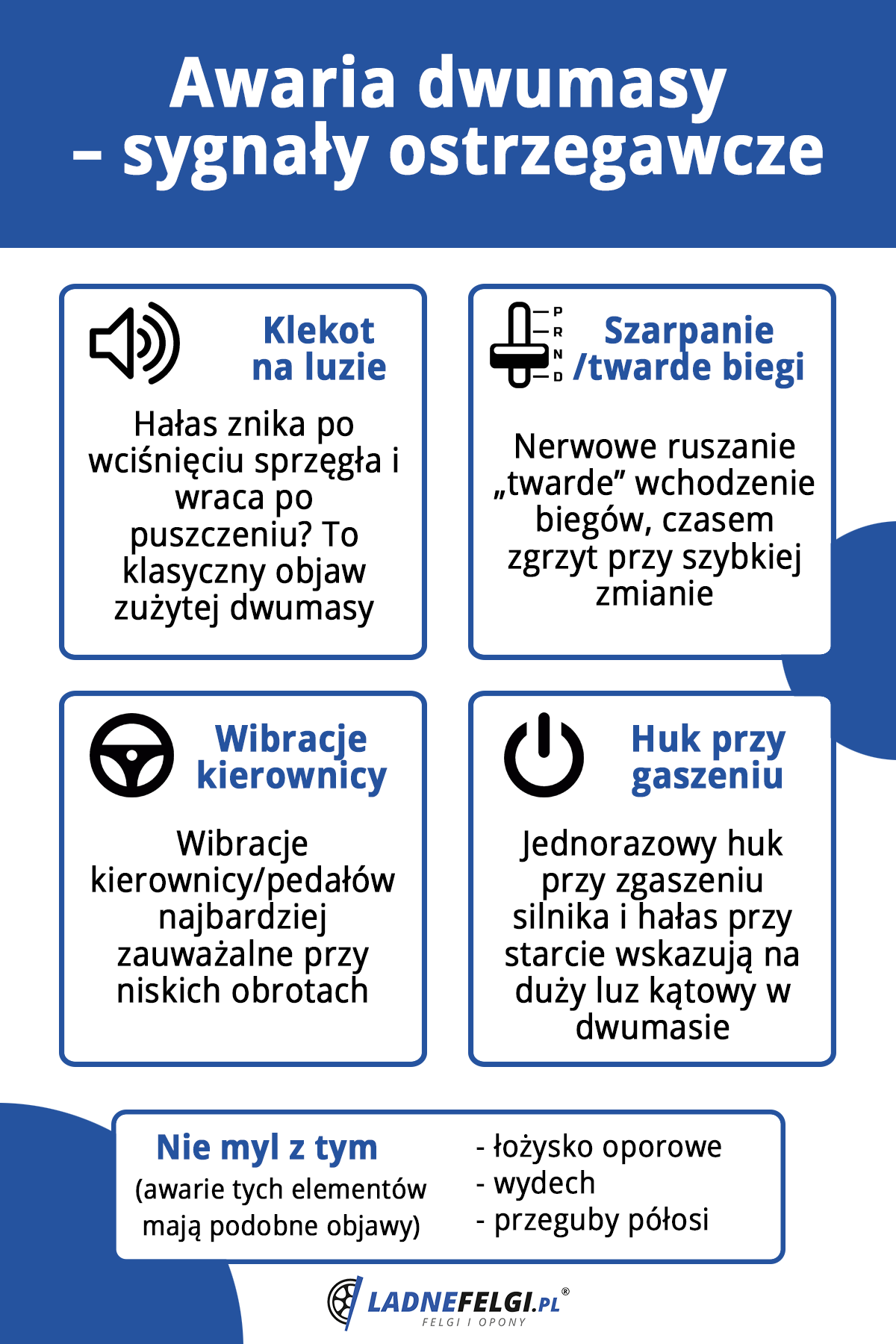

How to recognize a dual-mass flywheel failure? – Warning signals from the drivetrain

Sounds and vibrations – disturbing signals

Dual mass flywheel – wear symptoms begin with acoustics and vibrations:

- Clattering , knocking , or rattling sounds in the gearbox/clutch area, especially audible at idle. The sounds often disappear when the clutch is pressed and return when it is released – these are classic symptoms of a faulty dual-mass flywheel.

- Vibrations transmitted to the bodywork , steering wheel and pedals , most noticeable at low revs and when the engine is loaded (e.g. driving in too high a gear).

- Grinding or " hard " gear engagement , especially noticeable during quick changes - the result is disturbances in the operation of the vibration damper, which hinders synchronization in the gearbox.

If sounds and vibrations occur at the same time, it is a signal to urgently check the dual mass flywheel - the sooner, the lower the risk of secondary damage.

Clutch and engine problems – noticeable changes in driving

A faulty dual mass flywheel disrupts the operation of the entire drive unit:

- Jerks when starting and when changing gears - the vibration damper does not "smooth out" the torque impulses, which causes the drive to act nervously.

- Erratic idling , slight fluctuations in engine speed and delayed response to gas pedal – especially noticeable in diesels and small turbo petrols.

- A hard , unpleasant " thump " when turning off the engine or a noise when starting it - the angular clearance in a worn dual mass flywheel can cause a loud, one-time bang.

- Clutch slippage (higher RPM without proportional acceleration) - this is usually a disc/pressure plate problem , but a damaged dual mass flywheel can accelerate clutch wear and make the symptoms more severe.

In practice, the more advanced the dual-mass flywheel symptoms, the greater the risk of chain failures: from clutch wear to bearing and synchronizer damage in the gearbox. Early diagnosis and response can help avoid costly repairs to the entire system.

What are the risks of driving with a damaged dual-mass flywheel? – Don't ignore the symptoms!

Risk of damage to other components

Continuing to drive with a faulty torsional vibration damper is a direct route to a cascade of costly faults:

- Gearbox – Undamped vibrations "beat" the bearings and synchronizers , accelerating their wear. This causes whining, difficulty engaging gears, and ultimately, the need for a major overhaul .

- Crankshaft – increasing variable loads worsen the operating conditions of the main and connecting rod bearings. Prolonged operation can lead to excessive play and a drop in oil pressure.

- Clutch – A worn dual mass flywheel generates shocks that damage the discs , pressure plate , and release bearing . This often results in replacing the entire assembly (dual mass flywheel + clutch), rather than just the disc.

- Injection and fuel supply system – jerking of the drive and uneven operation at low revs may indirectly increase dose corrections, which in extreme cases leads to additional operational problems .

Conclusion: "Damaged dual mass flywheel – can you drive it?" Theoretically, yes, but every kilometer increases the risk of cost escalation and shortens the life of other components. The dual mass flywheel is a protective element for the rest of the system – when it fails, the entire drivetrain suffers.

Deterioration of driving comfort and safety

- Comfort decreases as increasing vibrations and noise tire the driver and passengers. The car loses its refinement, and a jerky feel appears.

- Risk of immobilisation – as wear progresses, the likelihood of sudden failure increases (e.g. disintegration of muffler components), which may result in towing.

- Road hazard – in extreme cases, fragments of a worn dual mass flywheel can block rotation or cause a violent, uncontrolled impact in the drivetrain. This poses a real risk of losing control of the vehicle.

In summary: "Damaged dual mass flywheel – can you drive it?" – it's not worth it. A quick diagnosis and repair is the cheapest and safest solution.

How much does a dual-mass flywheel replacement cost? – A significant expense in your budget

Component prices – parts and labor

There's no single answer to the question of how much a dual-mass flywheel replacement costs, as the bill includes both parts and labor. A dual-mass flywheel alone in popular, smaller cars typically costs around 1,000–1,500 PLN , while in mid-range and upper-class cars, SUV, high-powered versions, and delivery vans, the price often rises to 3,000–5,000 PLN , and in premium models, it can exceed this figure. In practice, replacing just the dual-mass flywheel is rarely done—a mechanic often recommends installing a complete clutch assembly (disc, pressure plate, and release bearing). This is a sensible approach: accessing the components requires disassembling the gearbox, so saving on parts and then re-doing the job after a few months would simply not be cost-effective. A clutch assembly adds another several hundred to several thousand PLN to the total cost, depending on the model.

The second component is labor . Replacing a dual-mass flywheel requires time-consuming disassembly of the gearbox, and often suspension or exhaust components as well. Independent garages typically charge around 500–700 PLN for simpler designs, but in many cars—especially those with 4x4 drivetrains, automatic transmissions, or tightly packed systems—the actual labor cost reaches 1000–1500 PLN or more . This may also include minor materials (disposable screws, lubricants, surface cleaning) and possible flywheel machining in cases where single-mass flywheels are used.

Factors influencing the final cost

The final price depends on several obvious but important variables. The car's model and make determine the availability of parts and the complexity of the work—popular cars tend to cost less than niche, sports, or luxury models. The engine type also matters: diesels often use more advanced damping solutions, while powerful petrol engines can "eat" the dual mass flywheels faster, which translates into the quality and price of the parts. The region and local hourly rates also matter—large cities are usually more expensive than smaller towns. The choice of workshop (Authorized Service Center vs. independent specialist) influences the cost of labor and the service warranty; at an Authorized Service Center, you'll pay more, but you'll receive documentation consistent with the manufacturer's recommendations. Finally, there are additional components that need replacing , which "come up" along the way: for example, the crankshaft seal , wheel bolts , bearing guides , and even drivetrain mounting bushings if they show excessive wear. Each of these items slightly increases the cost, but can extend trouble-free operation and prevent you from returning to the workshop.

Dual Mass Flywheel – Remanufactured or New? – A Choice Dilemma

New dual-mass flywheel – peace of mind guaranteed

Purchasing a new dual-mass flywheel is the simplest and safest option. You get a component manufactured to OEM specifications, with a full manufacturer warranty, factory balancing, and quality control. In practice, this means predictable, long-term, and trouble-free operation, as well as a reduced risk of warranty claims after installation. The only obvious drawback is the price. A new dual-mass flywheel is the highest expense, especially in premium cars or delivery vans, but it's also the most stress-free decision for drivers who want to put the issue behind them for years to come.

Dual mass flywheel regeneration – an economical option?

Dual mass flywheel remanufacturing involves restoring its parameters by replacing the arc springs, friction elements and spacers, bearings/guide bushings, and then precisely balancing the entire assembly. The financial aspect is tempting—a well-performed service can be 30-50% cheaper than purchasing a new component. However, it's important to be aware of the trade-offs: the quality of the remanufacturing strongly depends on the contractor's skills and machinery, the warranty can be shorter (or limited in scope), and the durability under real-world operating conditions may be shorter than that of a brand-new part. Therefore, verification of the company is crucial: experience, process documentation, the range of replaced components, the balancing protocol, and user reviews. In the hands of a reliable contractor, remanufacturing can be a sensible alternative, especially in commercial vehicles, where the balance of cost and predictable mileage is crucial.

Modern design

Modern design Perfect fit

Perfect fit High durability

High durability Free shipping within 24 hours

Free shipping within 24 hours

Individual project

Individual project Dedicated caregiver

Dedicated caregiver