Monoblock rims vs. bolted rims – which to choose?

Two solutions dominate the market: monoblock rims (i.e., one-piece rims) and bolt-on rims (constructed from two or three separate components). These two types of rims have their proponents and detractors – they differ not only in design but also in their intended use, durability, and comfort of use. Rims made from a single piece of material are valued for their strength and resistance to deformation, thus offering a longer lifespan and a reduced risk of failure. Bolted rims, on the other hand, allow for the replacement of individual parts, changes to technical parameters, and greater stylistic freedom – although they also require greater care and regular inspections.

In this article, you'll find a detailed comparison of both types—from design differences and performance features to their impact on performance, appearance, and maintenance costs. We'll explore the advantages of monoblock and bolt-on rims for everyday driving, and the benefits they offer for tuning or track use. We'll also assess the disadvantages of monoblock and bolt-on rims to help you decide which type is best for your car and driving style. Let's get started!

Contents:

- What's the difference between monoblock rims and bolt-on rims? Construction and production process

- One-piece vs. multi-piece rims – advantages and disadvantages of each solution

- Strength, flexibility, weight – comparison of the performance properties of monoblock and bolted rims

- Rim design – which models look better on different body types?

- Applications of monoblock and bolted rims – from motorsport, through tuning, to everyday driving

- Which type of rim is more problematic to maintain? Servicing and repair

- Price vs. Performance – Which Rims Are More Cost-Effective in the Long Run?

- How to choose the perfect rims for yourself? Key questions to ask yourself

What's the difference between monoblock rims and bolt-on rims? Construction and production process

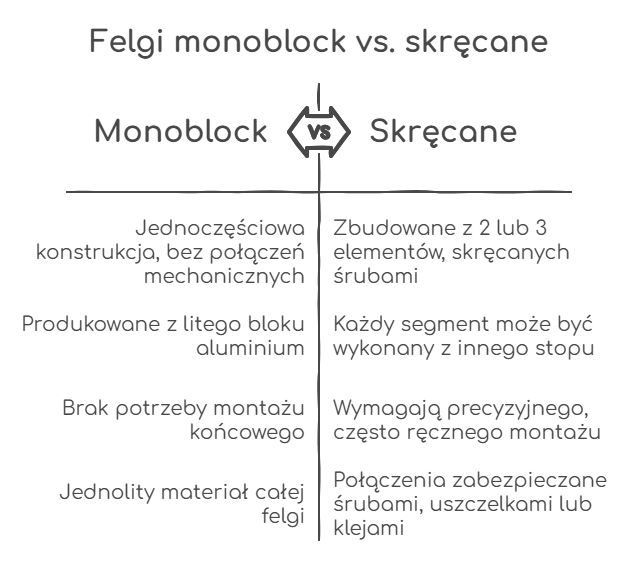

Let's start with what monoblock rims are. The monoblock design is based on a single, compact form – one-piece rims are created as a monolith, without any mechanical connections. They are manufactured from a solid block of aluminum or its alloy, and depending on the technology, they can be cast or forged. The forming process is crucial here – in forging, the metal is subjected to very high pressure, making it easier to achieve high material density and a uniform structure, free from internal stresses.

The construction of bolted rims, also known as multi-piece rims, is completely different. What are bolted rims? They consist of two or three separate segments – most often the disc (the central part of the rim), the barrel (the inner ring that forms the tire seating surface), and, in the case of three-piece designs, the outer rim. Each of these elements can be made of a different alloy, have a different machining process, and are then precisely connected to the others using steel or titanium bolts.

In practice, the differences between monoblock and bolted rims lie in the number of components, the connection method, and dimensional tolerances. In bolted rims, particular attention is paid to machining accuracy, as the fit of the parts must be absolutely tight—both due to tire pressure and the dynamic loads experienced during driving. The manufacturing process involves individual machining of each component, anodizing or painting, and then final assembly, often performed by hand.

It's worth noting that triple-piece rims use additional seals or technical adhesives to protect the contact points from moisture and road dust. Monoblock rims eliminate the assembly step—the rim is sent directly from the CNC machine for surface finishing.

One-piece vs. multi-piece rims – advantages and disadvantages of each solution

From the perspective of everyday use and operation, monoblock and bolt-on rims differ in both construction and functionality. One-piece rims ensure reliability and simplicity – the lack of bolted connections minimizes the risk of leaks, and the entire rim maintains high rigidity. Drivers who prioritize durability, low unsprung mass, and ease of cleaning often choose this type. Weather resistance, the lack of additional maintenance, and vehicle stability are also important for everyday driving – which is why the advantages of monoblock rims are appreciated by owners of passenger cars and sports cars.

Bolted rims, on the other hand, are distinguished by their modular design and the ability to replace individual components. Drivers seeking design flexibility and options for customizing the width, offset, or style of the rim are more likely to choose this type of model. In the event of damage to one component, there's no need to invest in a whole new set. This design is particularly well-suited to tuning and motorsports, where precise adjustments to every parameter directly impact the vehicle's handling. The advantages of bolted rims also include greater personalization options and the availability of variants dedicated to specific suspension systems.

However, limitations must be taken into account. The disadvantages of monoblock rims? The lack of options for subsequent modifications – the width, offset, and rim shape remain unchanged. Bolted rims, on the other hand, require more attention – regular inspection of bolted connections, more frequent leak inspections, and attention to the joint surfaces. Furthermore, the disadvantages of bolted rims include the increased overall weight of the rim and the greater risk of corrosion at the contact points.

| Characteristic | One-piece rims (monoblock) | Multi-piece rims (bolted) |

|---|---|---|

| Advantages | Simple construction Low unsprung weight Durability Easy to clean | Modular construction Possibility of replacing elements Personalization Perfect for tuning |

| Defects | No modification options Fixed parameters (ET, width) | More mass Risk of leakage The need for inspections |

| Resistance to weather conditions | High resistance – no contact points, better tightness | Inspection required - risk of corrosion at joints |

| Servicing | Minimal need for service | Regular inspection of connections and tightness |

| Application | Everyday driving, sports cars | Tuning, motorsport, individually modified cars |

Strength, flexibility, weight – comparison of the performance properties of monoblock and bolted rims

Before choosing a rim, it's worth considering which features will be key – stiffness, resistance to overload, weight, and the ability to compensate for deformation. From this perspective, the differences between monoblock and bolted rims take on practical significance.

Monoblock rims, thanks to their one-piece construction, offer high structural rigidity. They maintain stability during heavy braking or dynamic maneuvers, and the forces acting on the wheel are evenly distributed – this arrangement minimizes the risk of micro-deformation. This type of car rim weighs less than its bolted counterparts – the lower unsprung mass improves suspension response and translates into a more direct contact with the road. Their resistance to overload makes one-piece rims a popular choice among owners of sports and track cars.

Bolted rims, on the other hand, due to their multi-piece construction, offer greater mechanical flexibility – they better absorb energy in side impacts, reducing the risk of breakage. Their weight typically exceeds that of single-piece models, but this is often offset by the use of lightweight components. Multi-piece rims also allow for better weight distribution along the load axle, improving vehicle balance.

In short:

- Monoblock rims: stiff, lighter, resistant to overloads, ideal for sporty driving.

- Bolted rims: more flexible, more resistant to spot damage, better under variable loads.

Rim design – which models look better on different body types?

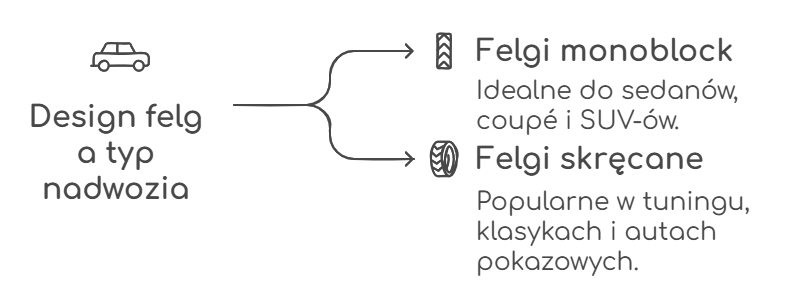

Monoblock models typically feature a simple, consistent design that complements the aesthetics of sedans, coupes, and modern premium SUV. Their smooth lines and symmetry ensure that, even with their large size, they don't visually dominate the bodywork.

Bolted rims, on the other hand, often consisting of a separate rim and spokes, allow for a more aggressive or detailed look – especially in the case of popular designs like black rims , which complement white, silver, or red paintwork perfectly. They are popular on tuned cars, classics, and show cars, where uniqueness and the ability to customize the color and finish of each element are key. Their layered construction adds depth, while unusual bolts and rims attract attention.

Applications of monoblock and bolted rims – from motorsport, through tuning, to everyday driving

It's fair to say that single-piece rims dominate everyday driving – they're cheaper, lighter, and typically more resistant to mechanical damage under typical use. That's why drivers of compact cars, SUV, and limousines most often choose them – especially when seeking a compromise between price, style, and durability.

On the other hand, multi-piece rims are a preferred solution for tuning and motorsport enthusiasts. They allow for precise adjustment of every parameter – from width and offset, to finish type and rim color. In motorsport, the ability to quickly replace just the rim in the event of damage, without having to purchase a complete set, is also crucial – a combination of cost-effectiveness and practicality.

In short:

- For everyday use and city driving – monoblock rims.

- For tuning, sport and aesthetic personalization – bolted rims.

Which type of rim is more problematic to maintain? Servicing and repair

Bolted rims pose more challenges in terms of maintenance. Their multi-piece construction means that each component—the rim, the center section, and the connecting ring—may require separate servicing. Users must consider the need to check bolt tightness, the risk of leaks at the joints, and the possibility of corrosion in hard-to-reach areas. Although replacing a single component can be cheaper than purchasing a new rim, the entire service process is more complicated and time-consuming.

Monoblock rims are significantly easier to maintain. Thanks to their one-piece construction, they pose no problems with joints or seals, and maintenance is limited to basic care. In the event of mechanical damage – such as curb deformation – all types of monoblock aluminum rims can be repaired by straightening at a specialized service center, without the need to disassemble the structure.

In short:

- For trouble-free use and easy maintenance – monoblock rims.

- For those ready for more demanding service in exchange for flexibility – bolted rims.

Price vs. Performance – Which Rims Are More Cost-Effective in the Long Run?

In the long term, monoblock rims prove to be more financially predictable – their one-piece construction reduces the risk of component failure and eliminates the need for specialized repairs. The reduced complexity of the design means easier maintenance, lower balancing costs, and no need for additional seals or joints. For many drivers looking for a cost-effective and durable solution, steel rims can also be an attractive alternative – less visually appealing, but extremely practical and resistant to road conditions.

Bolted rims, on the other hand, offer enormous customization potential but are associated with higher operating costs. While they can be rebuilt by replacing individual components, this procedure requires precise tools and technical expertise. Components for bolted rims can be more expensive and difficult to obtain, impacting the overall cost of ownership. However, in cases of intensive use – such as motorsport – this flexibility can prove worthwhile.

For drivers who don't want to worry about potential problems during daily driving, monoblock aluminum wheels are a more sensible option. Those who expect complete control over design and performance—and are willing to pay a higher price—will appreciate the potential of bolt-on wheels.

In short:

- For stable costs and ease of maintenance – monoblock rims.

- For full personalization and freedom of configuration – bolted rims.

How to choose the perfect rims for yourself? Key questions to ask yourself

Before you make a decision, there are a few key issues to consider.

1. In what environment will the car be used most often?

If your answer is based on city routes and longer journeys, single-piece rims are a practical choice, as they require less frequent maintenance. For track or tuning cars, multi-piece rims may be a better option, as they offer greater flexibility in modifications.

2. Do you care about personalizing the look of your wheels?

For those who value the ability to change the width, rim color or the way they fit the bodywork, bolted rims offer more configuration options than classic monoblocks.

3. How important is low wheel weight for driving dynamics?

In cars where every kilogram of unsprung weight counts, it's worth considering lightweight monoblock rims, especially forged ones. The reduced weight translates directly into improved handling and acceleration.

4. If a rim is damaged, do you want to be able to replace only part of it?

With multi-piece rims, it's often enough to replace just the rim or bolt. This is a significant advantage for drivers who want to avoid the cost of replacing the entire rim.

5. How important is resistance to everyday use to you?

If rims are to last for many seasons without special care, one-piece rims will be less demanding. Their construction better withstands the rigors of driving over bumps and reduces the risk of leaks.

Rims aren't just a feature – they're a practical decision that impacts a car's handling, comfort, and appearance. When choosing the right model, it's worth considering not only fashion, but also how and where you drive. Well-chosen rims can truly transform a car's character and make driving even more enjoyable.

Modern design

Modern design Perfect fit

Perfect fit High durability

High durability Free shipping within 24 hours

Free shipping within 24 hours

Individual project

Individual project Dedicated caregiver

Dedicated caregiver