Powder coating of rims - a comprehensive guide: the process, advantages and current price list

Powder coating is one of the most effective and durable methods of rim renovation, and has gained immense popularity in recent years among both automotive enthusiasts and those simply looking to refresh their car's appearance. This solution not only gives wheels a completely new character but, above all, provides them with durable, long-lasting protection against corrosion, chipping, and damage resulting from everyday use. Unlike traditional methods of rim painting, powder coating provides an exceptionally durable and even coating that copes with harsh road conditions.

The rest of this article will provide a comprehensive overview of the entire process – step-by-step explanations of surface preparation, paint application, and final curing. You'll also learn about the real benefits of this technology, its limitations, and when powder coating is most cost-effective. Finally, I'll present the current price list and the most important factors that influence the cost of painting aluminum wheels – from rim size and condition, to color selection and additional services. This guide will give you a comprehensive overview of powder coating aluminum wheels and help you make an informed decision about whether this solution is right for you.

How to Prepare Wheels for Powder Coating? The Key to a Lasting Effect

Professional preparation of wheels for powder coating is the foundation of the entire renovation process. Even the best powder coating will not ensure a lasting effect if the surface is not properly cleaned, degreased, and inspected for damage. This is why wheel renovation services place such great importance on substrate preparation—it determines the adhesion of the new coating, its corrosion resistance, and the final aesthetic.

Verification of technical condition and disassembly

The first step in preparing rims for painting is a thorough assessment of their technical condition . The tire, balance weights, and valve stems must be removed from the rim—only the bare rim can be restored. Specialists then inspect the rim for any warps, cracks, or other deformations that could affect driving safety.

If, upon inspection, it turns out that the rim is bent, it will be necessary to straighten the rim. This is a standard service offered by many restoration services. In most cases, straightening takes from 30 minutes to several hours, depending on the extent of the damage. Only after this preparation can the rim safely undergo further refinishing. This is a crucial step in the entire process of preparing the rim for painting, affecting both the durability and the proper handling of the wheel.

Removing the old coating – sandblasting, glass blasting or chemical treatment?

The next step is the complete removal of old paint, varnish, or corrosion. Depending on the condition of the rims and their type, several technologies are used.

Sandblasting is the most popular method, especially for heavily damaged rims or when refinishing steel rims. It involves directing a high-pressure abrasive stream at high pressure, effectively removing old coatings and rust, leaving a perfectly rough surface suitable for subsequent painting.

A more gentle method is glass-blasting , which works well on aluminum rims—especially those with complex spoke patterns or polished elements. Glass-blasting removes the coating in a more controlled manner, without the risk of excessively damaging the aluminum's structure.

The third option is chemical cleaning , which involves removing the paint using special solvents. This solution is used when you don't want to subject the rims to abrasives. This method is particularly useful for renovating steel rims, which require thorough paint removal without additional matting.

Each of these techniques has its own application, and the choice of the appropriate one depends primarily on the type of rims and their condition.

Degreasing and chemical preparation of the substrate

After removing the old coating, the rims undergo degreasing and chemical preparation . Special baths remove any remaining fats, grease, and dust that could impair powder coating adhesion. This is a crucial step—a perfectly clean surface guarantees even and durable coating.

Many professional services also use a zinc phosphating process. This chemical primer increases the rim's resistance to corrosion and improves the coating's adhesion, resulting in significantly longer-lasting wheel restoration and painting results. Only then do the wheels proceed to the actual powder coating stage.

Powder Coating Wheels – What Does It Involve? Step-by-Step Process

Once the wheels are perfectly cleaned, degreased, and prepared, you can move on to the most important step – the actual powder coating. This technology combines physics, chemistry, and precision machining, allowing for a result impossible to achieve with traditional spray painting. That's why powder coating is currently one of the most valued wheel restoration methods, used both in specialist workshops and in the automotive industry.

Powder Coating Application – The Magic of Electrostatics

To understand powder coating, it's worth starting with the basics: powder paint is a fine pigment combined with resin , forming a light, free-flowing powder. During the painting process, the powder particles are electrified in a special electrostatic gun . They then strike the rim, which is grounded and has an opposite charge. This attracts the powder to the surface like a magnet – evenly, precisely, and without material loss.

Electrostatics allows powder coating of rims to cover even the most difficult-to-reach corners of the rim , including curved spokes, recesses, and deep embossments. Furthermore, this method of applying the paint eliminates the typical problems of wet painting: there are no streaks, streaks, or unevenness. The coating is already uniform, even, and perfectly prepared for final curing. This is one of the greatest advantages of powder coating rims.

Polymerization, i.e. curing the coating in an oven

Once the rims have been powder-coated, the key stage of the entire process arrives: curing , or polymerization . The rims are placed in a special oven at temperatures of approximately 180–200°C . Under these conditions, the powder begins to melt, coalesce into a homogeneous mass, and then polymerize, creating a hard, compact, and exceptionally durable paint coating.

It's this step that makes powder coating so valuable. The coating created during the polymerization process is resistant to chips , road salt , rocks , car wash chemicals , and typical mechanical damage . This means that powder coating and wheel refinishing not only look great but also protect the rims for years to come.

Choice of color and finish – from classic to extravagant

The final step is choosing the color and finish. When it comes to powder coating, the possibilities are truly impressive. Most professional paint shops offer the full RAL palette , which means hundreds of colors—from classic black and graphite, through modern shades of anthracite and brown, to intense reds, yellows, greens, and unique specialty colors.

The choice of surface textures is equally wide. Rims can be finished in:

- high gloss – a luxurious effect that highlights the depth of color,

- satin or semi-matt – the most universal, natural-looking finish,

- full mat – elegant, minimalist and very modern,

- fine- or coarse-grained structure – an option often chosen when renovating steel rims or heavily worn alloy rims, as it masks minor imperfections well.

Powder coating alloy wheels offers enormous freedom of personalization, allowing every car owner to achieve exactly the look they desire. Whether it's classic aluminum wheel colors or more daring designs, the new coating will always be durable and damage-resistant.

Advantages and disadvantages of powder coating rims – is it a solution for you?

Powder coating is one of the most durable and professional methods of wheel restoration. While this technology offers many advantages over traditional painting, it's worth looking at it objectively—taking into account both its advantages and limitations. This makes it easier to decide whether powder coating is the best choice for your car.

The main advantages of powder coating

One of the key arguments for choosing this technology is its durability . Professionally performed powder coating of rims creates a coating that is extremely resistant to impacts, scratches, chips, road salt, and aggressive chemicals used in car washes. Thanks to the polymerization process, the coating is hard, stable, and protects the material even after many years of intensive use.

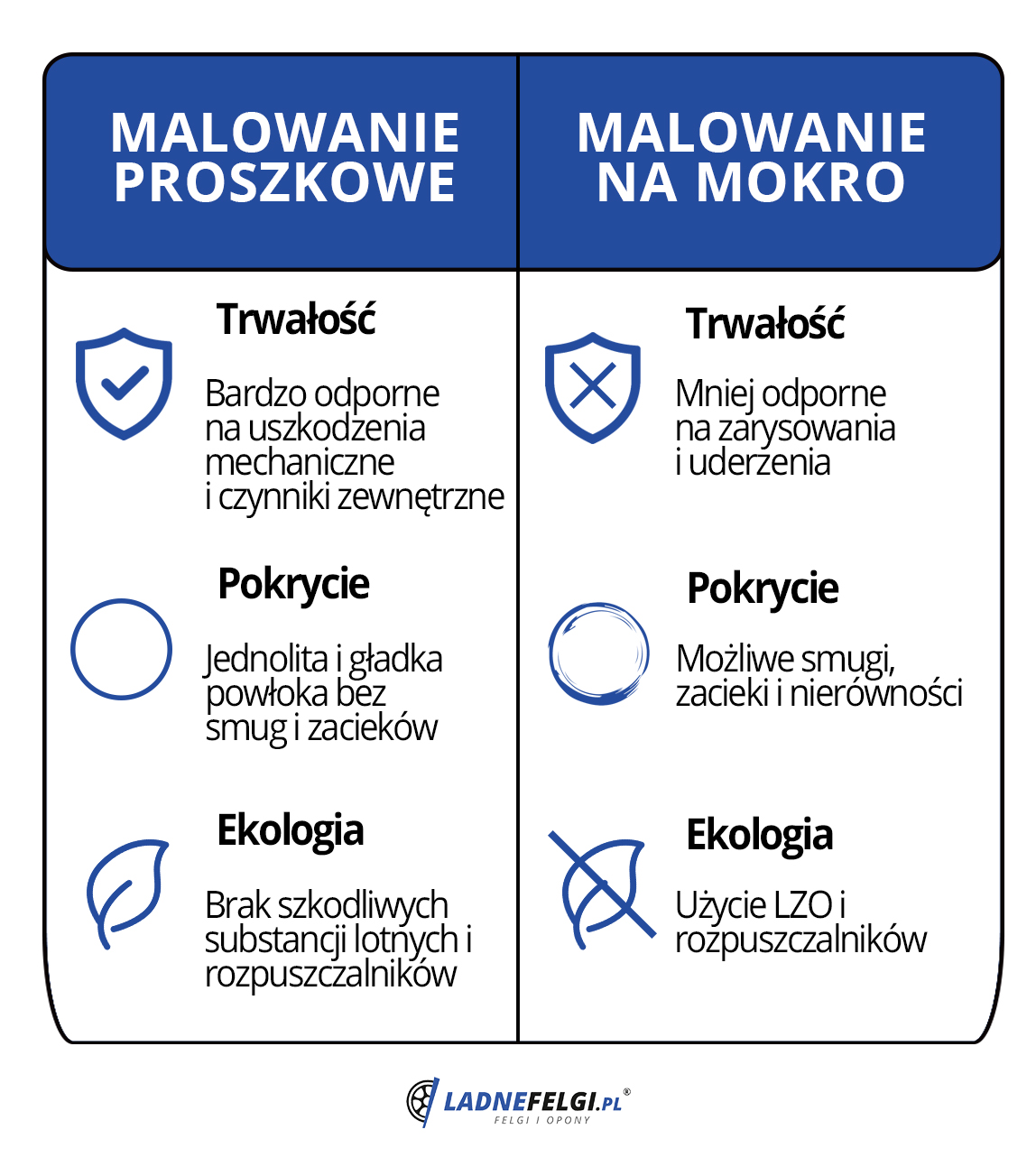

Another significant advantage is its flawless aesthetics . The end result of powder coating is a smooth, uniform coating without the streaks, streaks, or unevenness typical of wet painting. This means that wheel restoration using this method gives them a nearly brand-new appearance—regardless of whether you're working on steel or aluminum wheels.

The ecological aspect of this technology is also worth emphasizing. The powder process uses no volatile organic compounds (VOCs) or solvents , making it significantly more environmentally friendly. Furthermore, unused powder can be reused, reducing waste.

Added to this is its immense versatility—powder coating can be applied to both steel and aluminum rims, offering a wide range of color and finish customization options. All of these elements make the benefits of powder coating invaluable, especially when you're looking for a durable, aesthetically pleasing, and safe finish.

Potential disadvantages and limitations

While the technology has many advantages, it's also worth understanding its weaknesses. First and foremost, the powder coating process requires specialized equipment: a paint oven , electrostatic guns , and a properly prepared facility . This means that how to powder coat aluminum or steel wheels isn't a question that can be answered in the context of homework—it's simply not something you can do yourself.

The second limitation is the difficulty of spot repairs. If the coating is damaged in a specific spot, it's usually impossible to repair just one section , as is the case with traditional painting. The damage usually requires re-preparing and repainting the entire wheel to maintain a uniform finish.

Finally, it's worth mentioning the price. While powder coating is more durable and cost-effective in the long run, the initial cost is higher than spray painting or garage painting. However, the investment pays off in the form of long-term durability and protection for your wheels, making the price difference quickly unnoticeable.

In summary, the disadvantages of powder coating are relatively minor compared to its numerous advantages, but they are still important when making an informed decision. It's an ideal solution for drivers who value the highest quality and durability, not just a quick and inexpensive way to refresh their rims.

How much does powder coating rims cost? Price list analysis

Prices for powder coating rims can vary depending on rim size, the extent of preparation work, and the choice of color and finish. Unlike simple garage methods, the service performed in a professional paint shop involves a series of steps that significantly impact durability and the final result. Therefore, it's important to know exactly what constitutes a powder coating price, which elements are included in the service, and which are charged separately.

Powder coating price list – what is included in the standard service?

Standard wheel painting prices typically include the complete painting process: chemical surface preparation, powder primer application, a colored base coat, and a final clear coat, which provides shine and additional protection. The final step is polymerization, or oven-curing.

The average prices for powder coating for a set of 4 rims are as follows:

- Rims up to 16 inches – approx. PLN 350–600 per set,

- 17–19 inch rims – approx. PLN 500–900 per set,

- Rims 20 inches and larger – approx. PLN 700–1200 per set.

It's worth remembering that the price of wheel rim painting can vary depending on the reputation of the shop, the region, and the type of finish chosen. Some shops also offer packages in which the cost of chemical preparation is already included in the final price.

Additional costs you need to remember

Although the basic price list seems simple, the final price of rim renovation is influenced by several additional elements.

Sandblasting or bead blasting of rims – usually priced separately, especially if the rim requires complete removal of the old coating or shows signs of corrosion. Average cost per set: 120–250 PLN .

Wheel straightening or welding – services depend on the extent of the damage. In most cases, the cost of straightening a single wheel is 50–150 PLN , while welding cracks can cost 50–200 PLN per component.

Tire service – tire removal and installation, as well as wheel balancing, are usually additional fees. A full service typically costs 120–200 PLN .

Custom colors , special effects , and premium finishes – chameleon colors, metallic paints, candy, chrome, or special textures can add 100–300 PLN per set. The same applies to very striking high-gloss finishes or two-coat paints.

When combining sandblasting and painting, workshops often offer packages such as "sandblasting and painting rims, price - set 17-18 inches from PLN 550 ", but special effects or repairs are always charged additionally.

Sample calculation – comprehensive rim renovation

To illustrate how much it costs to paint aluminum rims, let's prepare a full simulation for one of the most popular sizes — 18-inch rims:

| Service | Approximate price |

|---|---|

| Removing tires + valves | 40–60 PLN |

| Sandblasting the set | 150–200 PLN |

| Powder coating (RAL standard) | 600–800 PLN |

| Tire mounting + balancing | 150–200 PLN |

| Together: | 940–1260 PLN for an 18" set |

For a special color or if the rims need to be straightened, the cost can increase to approximately PLN 1,100–1,500, which is still an attractive price for a full, multi-year renovation.

This powder coating price list allows for a realistic assessment of the potential cost of a comprehensive restoration. It also shows that, while it's not the cheapest method, it offers an exceptional price-to-durability ratio and visual impact.

Modern design

Modern design Perfect fit

Perfect fit High durability

High durability Free shipping within 24 hours

Free shipping within 24 hours

Individual project

Individual project Dedicated caregiver

Dedicated caregiver