The production process of aluminum rims

When deciding on aluminum rims, we often face a significant challenge. The wide selection of stores offering this type of product leaves us bewildered – we don't know whether to base our choices solely on appearance, we wonder why seemingly similar pieces differ dramatically in price, and we don't know which ones will be more durable and last longer. To help you understand the fascinating world of aluminum rims, we'll present various production methods for popular alloys , paying particular attention to the impact these methods have on the functionality of the finished products.

Different methods of producing aluminum rims

When visiting any rim shop, the first thing that strikes us is the sheer variety of choices. Differing not only in size and color, the finishes can be both delightful and terrifying due to the price tag. Where do these vast differences come from? There's only one answer: the manufacturing process is to blame.

The most popular method for producing aluminum rims is the low-pressure method . This involves applying pressurized air to the aluminum while it is in liquid form during casting. Next, after it cools, specialists inspect the rim for any imperfections that could impact its durability. If the test passes, further inspection of the product occurs, this time from the inside using an X-ray machine. If no objections are found, the rim is heated at a high temperature and slowly cooled. This process ensures greater durability and strength. After the process is complete, mounting holes are drilled and the rim is painted.

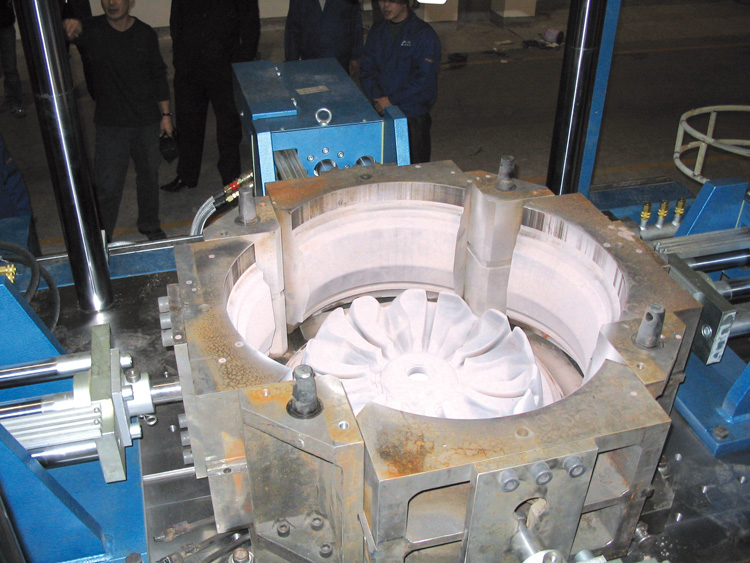

Another method for producing rims is called gravity . It's the simplest and cheapest, and—as you might guess—the least effective . Unfortunately, it doesn't use X-rays, which can reveal hidden flaws. It also doesn't use air to form the product; instead, it relies, as the name suggests, on the force of gravity. This is how the aluminum is transferred to the die, where it is formed.

Anyone with even a passing interest in motoring is undoubtedly familiar with the wheel forging method . While incredibly popular and considered the best, it's actually not, especially for everyday road users. Of course, it produces exceptionally durable wheels, but it comes with a high price that's disproportionate to the capabilities. What's the process like? Aluminum is heated to a high temperature and then subjected to enormous pressure in a precision press, which compacts and shapes the raw material until it achieves the desired shape. Such a wheel, as mentioned earlier, is characterized by extraordinary durability, thanks to the high density of the material obtained through compaction.

There's another method for producing rims: rolling . The resulting rim will be as durable as forged rims, but unfortunately, it's also similarly expensive. With this method, the production process is as follows: special rollers compact the material until it achieves the desired shape. This affects the rim's density, making it exceptionally durable.

Which method of obtaining rims is best?

Unfortunately, we can't give you a clear answer to this question. When visiting a rim shop and wanting to make the best decision, we need to know what we're looking for. If the rim is to be exceptionally durable, we should opt for rims made by forging or rolling, but if we want to choose wisely, it's best to look at rims made using the low-pressure method. However, this doesn't mean compromising – products made this way are also durable and perfect for everyday driving.

Modern design

Modern design Perfect fit

Perfect fit High durability

High durability Free shipping within 24 hours

Free shipping within 24 hours

Individual project

Individual project Dedicated caregiver

Dedicated caregiver