OE VW Steel Rims 16 5x112 AUDI A3 A4 b5 b6 b7 A6 Q2 Q3 VW PASSAT B6 B7 B8 GOLF 6 7 8 9 T-ROC Tiguan Touran Skoda Octavia SuperB SEAT Alhambra Altea Leon Toledo

- Original VW DEMO rims were intended for original equipment use in VW vehicles. Tires were mounted on the rims, but the wheels were never mounted on a vehicle or used. The rims may have minor assembly scratches and minor paint chips at the weld seams.

17 YEARS ON THE MARKET

17 YEARS ON THE MARKET Together, we develop the Polish economy

SECURITY

SECURITY Possibility of free order insurance - Trusted Shop Protect

QUALITY CERTIFICATE

QUALITY CERTIFICATE Alloy wheels have ISO, VIA JWL certificates proving their high quality

GUARANTEED QUALITY

GUARANTEED QUALITY Aluminum Rims are covered by a 3-year warranty

STATIONARY SHOPS

STATIONARY SHOPS Opportunity to look at the goods closely, direct contact with an expert

Available variants!

Steel rims of Volkswagen OE in your car - choose a proven solution!

Steel rims have a large group of recipients and there are two reasons for this: economic and practical. These rims will work for drivers who are looking for a budget solution for their car. Steel rims together with winter tires are used as the second set of wheels. This is a very common solution - with the onset of winter, popular nibs rule the streets. So if you are looking for steel rims from a proven manufacturer, you've come to the right place!

Original steel wheels Volkswagen OE.

The wheels were manufactured by a globally renowned brand specializing in the production of passenger cars. The high quality of the product combined with its low price makes Volkswagen OE steel wheels the perfect solution for your car in winter conditions. Each wheel is packed in a separate branded box that protects it from damage during transport.

When you buy this product, you will receive from us: ✅ 1 x new steel rim, ✅ 1 x valve, ❌ IMPORTANT! The set does not include bolts / nuts ➡️ accessories

Volkswagen OE - powder coated rims.

The steel rims of Volkswagen OE are characterized by high quality of workmanship. And the process of making nibs is complex and multi-stage. Thanks to the use of an electrostatic painting method, i.e. powder coating, the rims passed the tests performed in a salt chamber without any problems, reflecting difficult weather and road conditions.

What is powder coating? Powder coating is the application of electrified powder paint particles to the conductive surface of the metal. The painted elements are heated to a temperature of 140-200 ° C, as a result of which the powder melts and polymerizes.

What are the advantages of powder coating? The resulting paint coating is resistant to corrosion, chemicals, high temperature and mechanical damage.

Research and testing as a guarantee of high-quality steel wheels

The rims manufacturing process ends with a test cycle. On an automated line, tests are carried out for each rim:

✅ tensile test,

✅ radial runout (permissible deviations are up to 1,2 mm) and dynamic balancing,

✅ corrosion resistance,

✅ diagnostics with the X-ray machine of the integrity of the structure and the absence of microcracks are performed,

✅ strength under load,

✅ tightness,

✅ quality of the varnish coat.

The above tests are carried out on 100% production of steel rims.

Only rims that have pierced all of the above-mentioned are placed on the market. tests. Thanks to this, you can be sure that the products are 100% functional and tested.

Steel wheels manufactured in certified factories.

The specification defines the requirements for a quality system for products in the field of design or production development, installation, and servicing in the automotive industry. The factories where steel wheels are produced are certified in accordance with international quality management standards. Most production processes are fully automated. Advanced technologies combined with international automotive industry standards enable the production of reliable products – high-quality steel wheels.

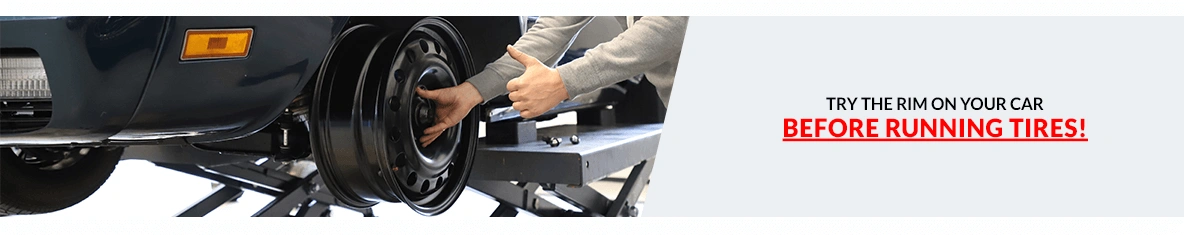

Check the nibs before fitting the tires.

After receiving your order, check that the package contains all the products you have purchased. Accessories can be glued to the bottom of the carton or they can be in one of the four cartons.

At the very beginning, before assembly, check that the rims fit the car, do not have deviations, do not rub against the suspension elements and do not protrude beyond the wheel arch. Nibs should be tried on both axles of the vehicle It is important to verify the goods BEFORE mounting the tires on the rims. The fitting of tiresis unnecessary and will prevent the correct diagnosis of the product. If you visit a service / workshop, inform the vulcanizer to perform the above steps first.

It should also be remembered that the tolerance of the hole diameter is 0.3 mm. The central bore is tapered towards the outside. Only when the screws on the opposite sides are tightened, the rim is properly centered and the play is leveled.

Quality confirmed by customer opinions.

We receive numerous positive opinions from our customers in Trusted Shops and photos of cars on our rims, which are regularly published on our Facebook, Instagram and gallery website.

Since 2008, we have been selling steel rims, aluminum rims, TPMS sensors, assembly accessories. Our products, services and knowledge are used, among others, by authorized car repair shops all over Poland. There are already over 100,000 on the roads of Poland and Europe. cars fitted with our rims. It's time for YOU to trust us!

Tech specs:

The model:determines the appearance of the rim. By entering the model in the LadneFelgi.pl store search engine, you can search for rims in different colors and with other parameters.

Rim size: refers to the diameter of the rim given in inches (1 inch = 2.54 cm). The possible sizes are predetermined by the vehicle manufacturer. Using rims smaller than those specified by the manufacturer is not allowed.

Rim width: is measured between the rim flanges. The dimension is in inches. When choosing tires, take into account the width of the rim and the car manufacturer's recommendations.

Wheel PCD: determines the number and spacing of mounting holes. This is the diameter of the circle with the centers of these mounting holes. The diameter of the circle is given in millimeters.

ET, offset: is not a strictly defined parameter, such as spacing. It depends on the width of the rim. ET is given in mm. The smaller the offset, the more the rim is, which increases the wheelbase, positively influencing the car's stability. The service book or ASO provides only the parameters of the currently installed rims.

Center bore: it is the dimension of the rim center hole diameter given in mm. If the car has a smaller hub diameter, centering rings are used. The ring is used to center the rim in relation to the car's hub. After screwing it, no force acts on it. It is a safe solution used by all rim manufacturers.

Color: determines the colors in which the offered item was made. Pictures are taken under natural lighting.

Product presentation on YouTube: copy the link and paste it into your browser's address bar to watch the 360° wheel video.

Modern design

Modern design Perfect fit

Perfect fit High durability

High durability Free shipping within 24 hours

Free shipping within 24 hours

Individual project

Individual project Dedicated caregiver

Dedicated caregiver